Our systems stand out for their exceptional durability, unmatched reliability, and long-standing reputation you can trust.

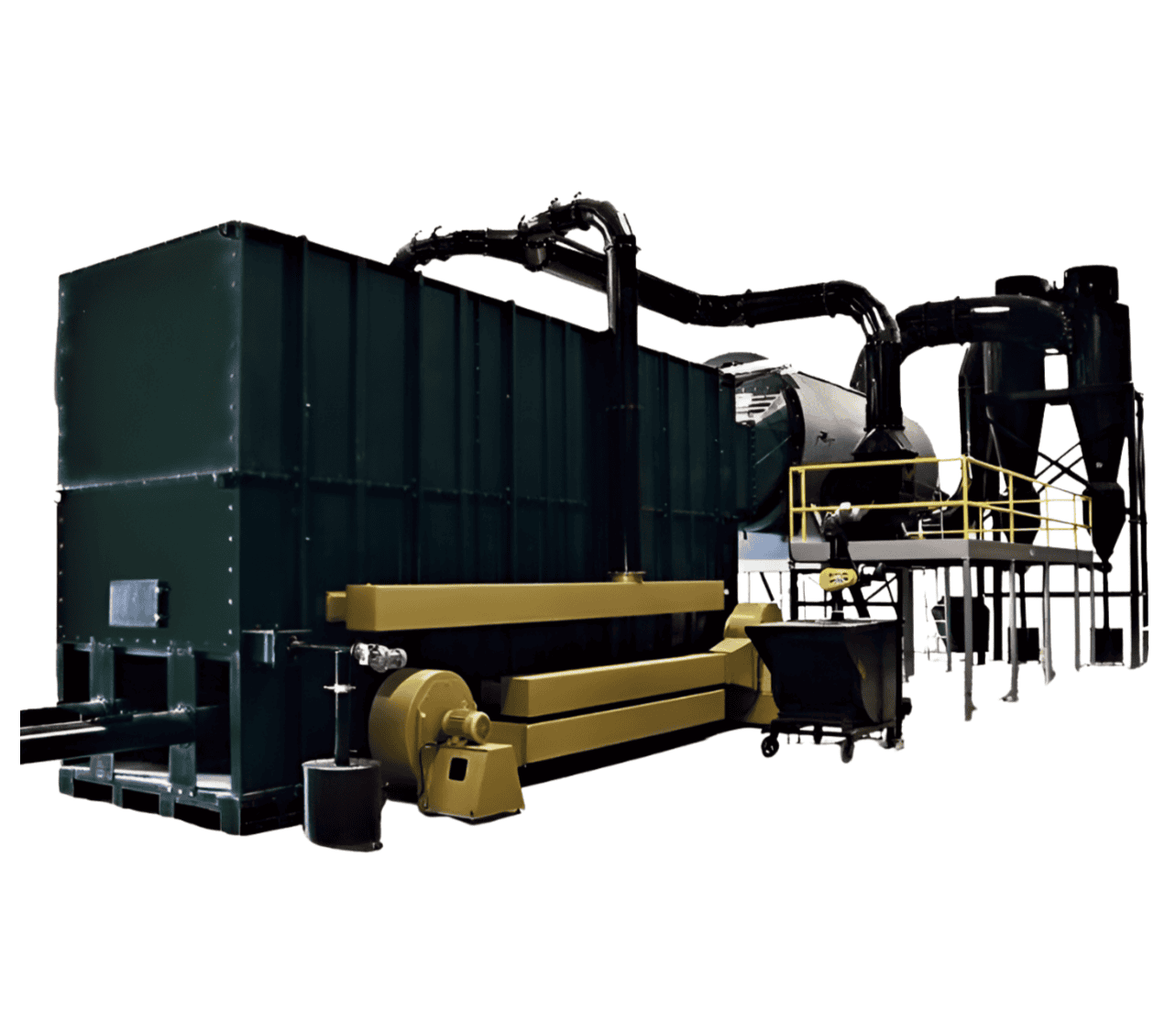

Waste-to-Energy Systems

AgriPower Manufacturing designs and manufactures high-quality systems that convert waste into energy. Our systems use forest residues, various biomass sources, and municipal solid waste (MSW) as fuel to generate affordable electrical power and thermal energy on-site, both on-grid and off-grid. These modular and transportable systems are especially beneficial for locations with high hot water, heated air, and steam demand, where traditional production methods would be costly.

Thermal Combustion Units produce warm air, hot water, and steam and will meet or exceed all EPA standards. Each system can process 1 to 60 tons of waste per day in an environmentally friendly manner, producing between 500,000 and 25,000,000 BTUs per hour (net) of heat energy.

Building on our proven Heat-Only systems, we are excited to introduce a new product engineered explicitly for the Combined Heat and Power (CHP) market. With the combination of a custom-designed waste heat steam boiler and a state-of-the-art, high-efficiency, steam-powered electric generator, our Combined Heat and Power Systems can generate from 100 kW to 7.5 MW (gross) and from 75 kW to 7.0 MW (net) of continuous, low-cost electric power by combusting 12 to 300 tons of suitable waste per day.

Benefits

Benefits

Extended Burn Chamber

Extended Burn Chamber

An added secondary chamber extends the dwell time of the combustion gases for up to 1.3 seconds at high temperatures. This added dwell time facilitates additional combustion of unwanted particulate and helps prevent gas emissions.

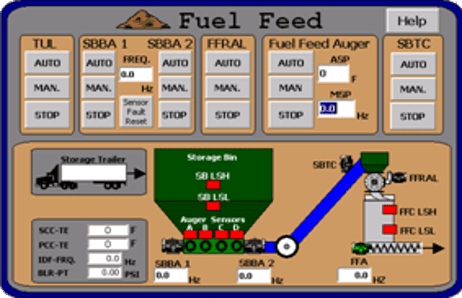

Completely Automated Combustion Processes

Completely Automated Combustion Processes

Our systems are controlled by Variable Frequency Controls (VFDs) to regulate feed rates, control temperatures, and meet load demands. Create the most efficient and cleanest combustion process possible while controlling fuel costs.

Effective & Clean Automatic Deash System

Effective & Clean Automatic Deash System

No ramp-down or burn-down processes significantly increase the system's operating hours. Additionally, ash can be easily and safely emptied without disrupting operations.

Combust a Wide Variety of Fuels

Utilize fuels with varying moisture and ash content, including agricultural and forest waste, wood, cardboard, and a diverse range of other waste materials.

Cast Refractory

Cast refractory construction provides a strong seal within the firebox, ensuring years of operation. Additionally, the cast refractory allows for easy repairs and parts replacement when necessary.

Remote Monitoring

We provide comprehensive support through our off-site control package, assisting you remotely with any questions or troubleshooting needs.

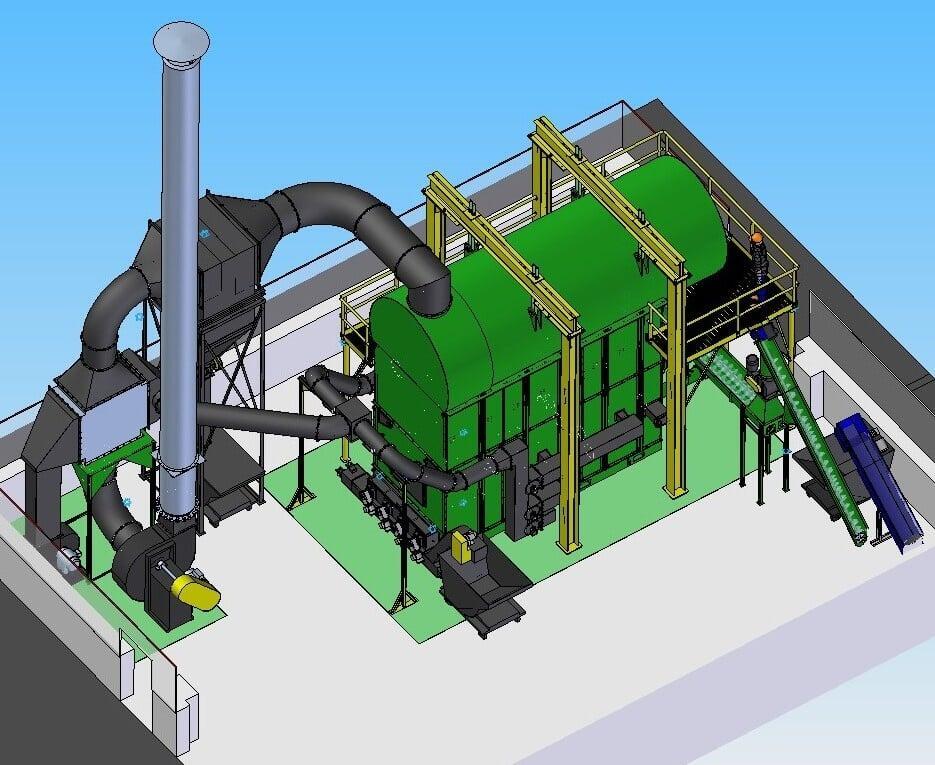

Modular Design

Our modular design reduces installation time and minimizes footprint. It also allows for various flexible layouts and accommodates different building site dimensions.

Applications

Our systems help commercial, industrial, agricultural, governmental, and other organizations manage their waste responsibly and efficiently. These solutions promote energy independence and sustainability for all users by converting waste into cost-effective heat energy and electricity.

They have been installed in various settings, including schools, greenhouses, hospitals, wood processing facilities, and numerous municipal locations. Many have successfully operated for over a decade, demonstrating their reliability and impact.

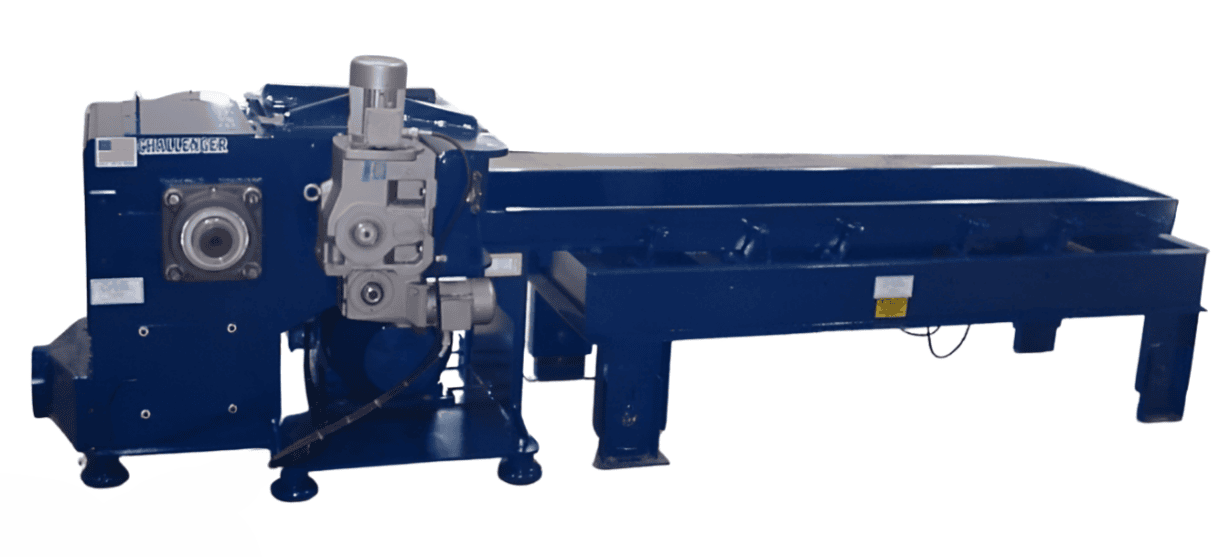

Waste Reduction Grinders

AgriPower Waste Reduction Grinders are designed to deliver exceptional performance in reducing various waste materials. These grinders can process large volumes of biomass waste, plastics, paper, and cardboard, making them an essential tool for businesses looking for effective waste management solutions.

Comprehensive Range of Grinders

AgriPower Manufacturing provides the most comprehensive range of waste-reduction grinders available. Our product lineup includes hopper-fed and horizontal-fed models, ensuring we have a solution for your waste reduction needs.

Versatile and High-Capacity Options

Grinders are available in sizes 1 to 10 feet wide, with production capacities between 500 and 40,000 pounds per hour. This versatility allows our grinders to be used in various settings, from small-scale operations to extensive industrial facilities.

Commitment to Quality

We take pride in our manufacturing and quality control, ensuring the best-built grinders in the industry. Our careful monitoring guarantees reliable, low-maintenance, and competitively priced equipment. With an in-house design and engineering team, we can customize each waste reduction system to meet specific customer needs.

Storage and Material Handling

Along with our grinders and waste-to-energy systems, we offer a comprehensive range of storage and material handling equipment, all custom-designed to meet our customers' needs.

Available Options

Auger systems, Blowers, Chute Separators, Disc and Vibratory Screeners, Fuel Transfer Systems, Magnets and Metal Detection and Removal Solutions, Pit Storage Systems, Silo Storage, Truck Unloading Systems, Vibratory, Drag Chain, and Belt Conveyors, and Walking Floors.