FIXCUT Cutting System

The FIXCUT cutting system is meticulously designed with several key components that work together to ensure optimal performance and durability.

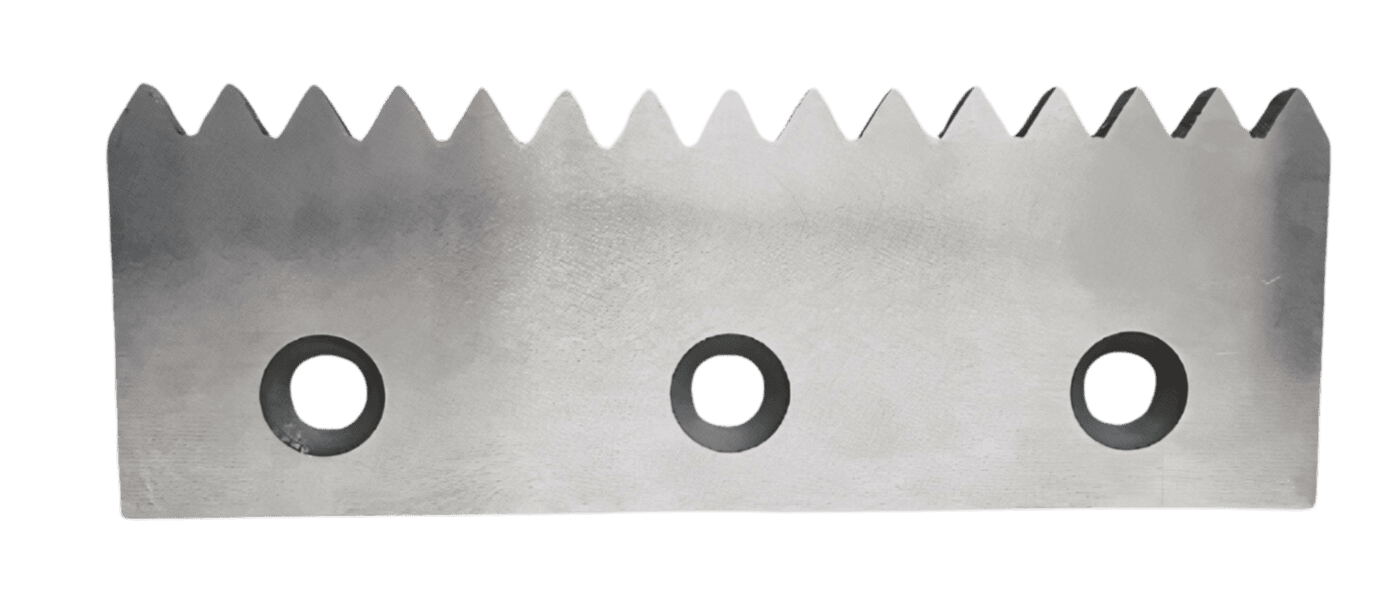

Stationary Cutting Bar

The one-foot stationary cutter bars provide a stable base for the cutting action. These bars, combined with the innovative cutter design, enhance the precision and consistency of each cut.

High-Grade Alloy Steel Cutters

The cutters are made from high-grade alloy steel and designed for maximum efficiency and durability. This material choice ensures that the cutters are strong enough to handle even the toughest materials without compromising performance. These cutters are designed to wear down rather than shatter, enhancing safety and reliability. To maintain effectiveness, rotate the relatively worn cutters to maximize their lifespan. The edges that wear the most can also be sharpened before rotation.

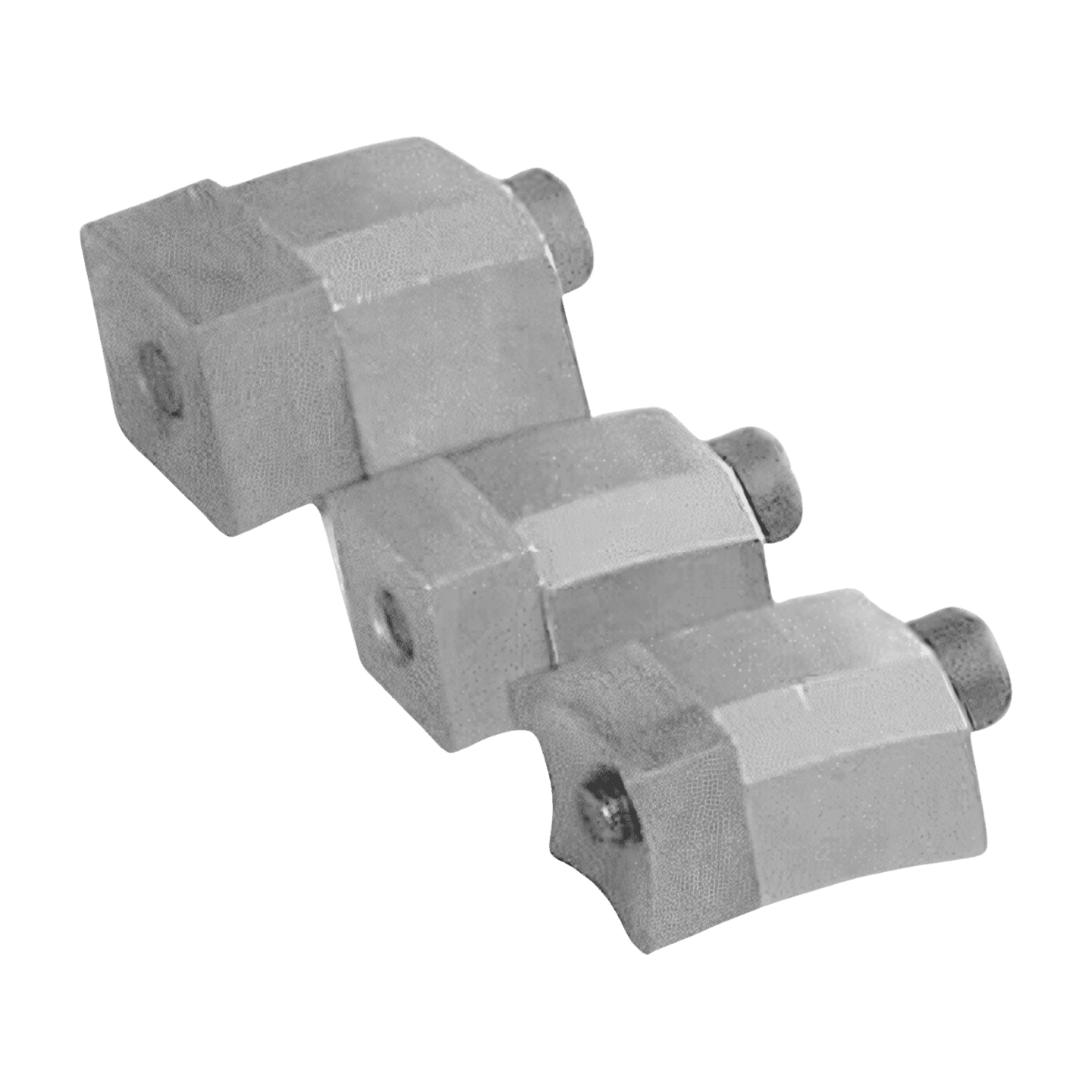

High-Definition Rotor

One of the most impressive aspects of the FIXCUT system is its main rotor and shaft, meticulously constructed from a single piece of solid steel. This innovative design offers remarkable durability and strength, guaranteeing outstanding performance in even the most challenging environments. To accommodate different operational requirements, the FIXCUT system offers rotors in various sizes:

10-inch diameter | 14-inch diameter | 18-inch diameter | 22-inch diameter

High-Definition Recessed Rotor

The rotor is a solid piece of steel with recessed cutters that enable tighter tolerances, improving efficiency and processing smaller particle sizes. This design allows for better definition and ensures a more consistent product in a single pass.

- Material is transferred to the center, eliminating heat buildup.

- Reduces exposure by countersinking the cutter.

The high-definition recess rotor is also interchangeable with rotors of the same size in our other Challenger grinders.